Introduction to On-Site Dynamic Balancing Services

Maintaining the stability and performance of machinery is always a top priority in any industry. On-site dynamic balancing services are the optimal solution to minimize vibration and wear, thereby extending the life and improving the efficiency of equipment.

What is on-site dynamic balancing?

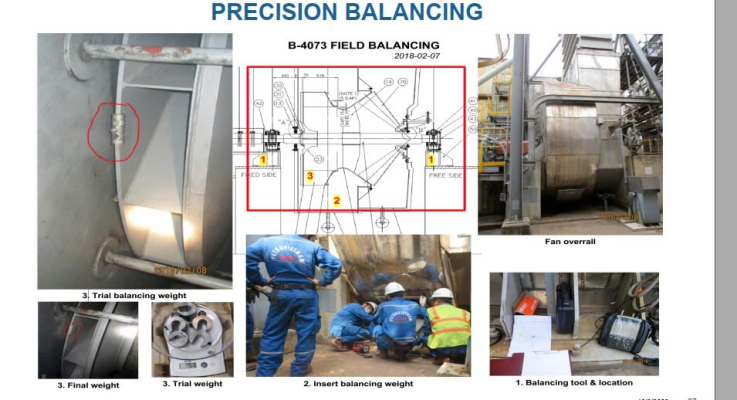

On-site dynamic balancing is the process of measuring and adjusting the mass distribution of rotating parts to minimize vibration and ensure smooth operation of machinery. This method is usually performed right at the installation location of the machine, saving time and reducing transportation costs.

Benefits of on-site dynamic balancing services

- Reducing vibration and noise: The dynamic balancing process helps eliminate uneven impact forces, minimizing vibration and noise caused by machinery.

- Prolonging equipment life: Properly balanced equipment will operate more stably, thereby reducing wear and prolonging its life.

- Improve operational efficiency: Stable machine operation helps improve production efficiency and minimize unexpected incidents.

- Save maintenance costs: On-site dynamic balancing helps minimize machine downtime and maintenance costs, thereby optimizing business profits.

Why choose our service?

TITEK CORP is proud to be a professional and effective provider of on-site dynamic balancing services. With a team of experienced technicians and modern equipment, we are committed to providing optimal solutions, helping your business feel secure about the operation of the machinery.

Contact us today for advice and experience high-quality on-site dynamic balancing services!

Vi

Vi